Rotor Spring Band Clamps are self-tensioning sealing components, which ensure a leak-free sealing of hose/spigot joints. Utilizing austempered, high-tensile chrome-vanadium spring steel, the final product indicates great flexibility and strength, ensuring a reliable, leak-proof connection of a hose to a fitting. Once the Rotor Hose clamp is installed on the hose joint, there will not be any need to re-torque or re-adjust the clamp over time (compared to a typical screw type clamp).

Spring band clamps as hose clamps have proven themselves in the water cooling sector and have become essential for many users and systems.

Hose clamps are important for fixation of tubing on barbed fittings without a union nut. These spring band clamps can be opened hassle-free by hand without any tools. It’s even easier with pliers!

| NO. | Parameters | Details |

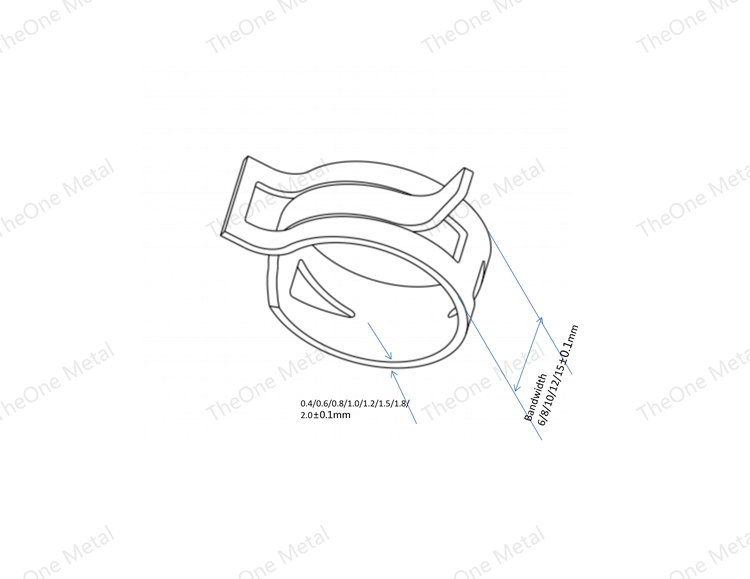

| 1. | Bandwidth | 6/8/10/12/15mm |

| 2. | Thickness | 0.4/0.6/0.8/1.0/1.2/1.5/1.8/2.0mm |

| 3. | Size | 4-52mm |

| 4. | Samples Offer | Free Samples Available |

| 5. | OEM/ODM | OEM/ODM is welcome |

| TO Part No. | Material | Band Surface Treatment |

| TOSG | 65Mn Spring Steel | Zinc Plated |

| TOSD | 65Mn Spring Steel | Dacromet |

| TOSC | 65Mn Spring Steel | Black |

Spring hose clamp have a wide range of use, can resist the corrosionand, rust in marin environments. The products are workmanship and durability.

Clamps are dopted in securing hoses, pipe, cable, tube, fuel lines etc.Perfect to apply in both indoor and outdoor situation as automotive, industrial, boat, marine,shield, household and so on.

spring hose clamp are self-tightening, sealing elements made from tempered spring band steel offeringa high level of flexible to ensure reliable, leak proof connection of a hose to s fitting.

Re-torque and re-adjustment are not required after installation.

Maintains constant tension throughout all pressure and fluid systems of almost any application.

Leak-proof solution for applications, ranging-40°F-392°F